Blog

How to Prevent Wine Glass Bottle Cracking: The Complete Bulk Purchasing Guide for Wineries

For wineries purchasing glass bottles in bulk, cracking or bursting bottles can lead to serious losses — damaged inventory, leakage during transport, increased logistics costs, and even safety hazards.

Many producers assume breakage is random.

In reality, it almost always comes from bottle strength, internal stress, poor forming quality, or improper logistics handling.

This guide explains:

✔ Why bottles crack

✔ How professional factories prevent defects

✔ What technical standards you should require

✔ Warehouse & transport best practices

✔ How to choose a reliable bulk supplier

By controlling these factors, wineries can reduce breakage rates by 90%+.

Why Do Wine Bottles Crack or Burst?

1. Internal Pressure (Fermentation & Carbonation)

Sparkling wine and secondary fermentation wines generate CO₂.

Typical pressure:

• Still wine → 0.2–0.3 MPa

• Sparkling wine → 0.8–1.2 MPa

If bottle strength is insufficient:

-

shoulders crack

-

bases burst

-

corks eject

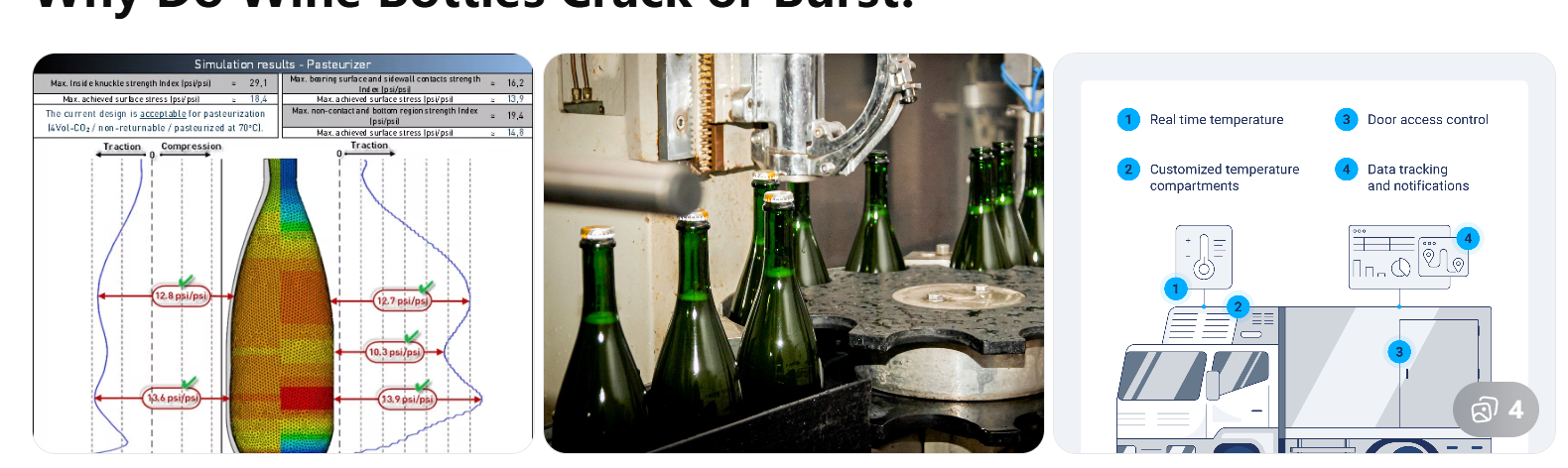

2. Manufacturing Defects

Low-quality bottles may contain:

• uneven wall thickness

• bubbles or stones

• weak shoulders

• residual internal stress

• poor raw materials

Even tiny defects dramatically reduce strength.

3. Thermal Shock

Sudden temperature differences cause uneven expansion.

Examples:

-

cold warehouse → hot truck

-

winter storage → filling line

-

direct sunlight

This creates stress fractures.

4. Mechanical Damage

• over stacking

• pallet compression

• vibration

• bottle collision

Poor packaging multiplies losses.

Factory Solutions That Prevent Cracking

High-Purity Raw Materials

Professional factories use:

• ≥99.5% silica sand

• low iron content

• multi-stage magnetic purification

Result:

✔ stronger tensile strength

✔ fewer weak spots

✔ better transparency

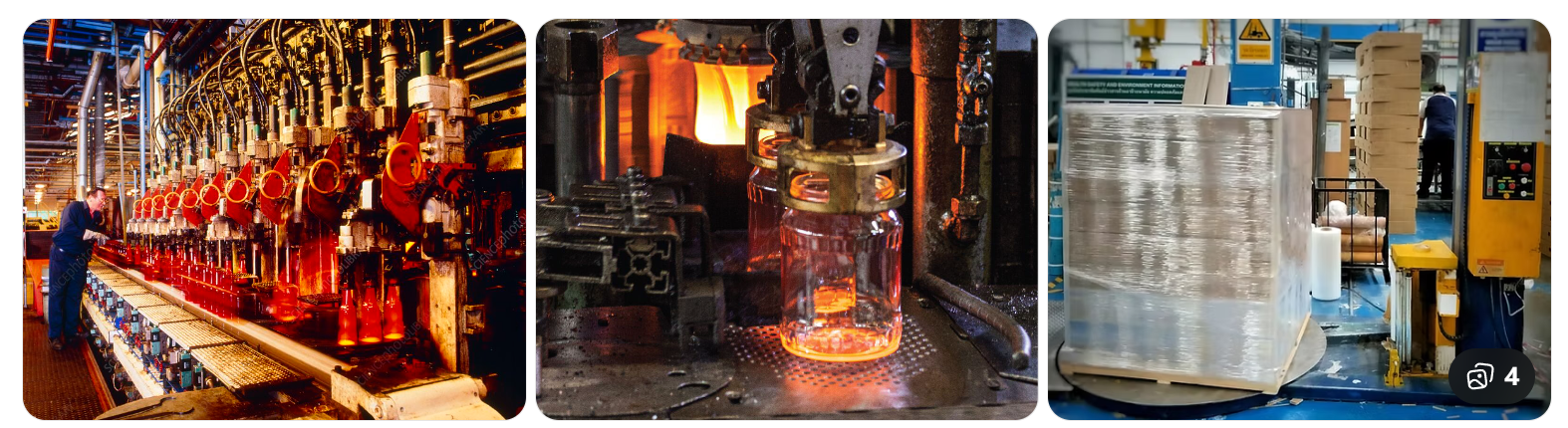

Precision Forming

Modern CNC machines control:

• wall thickness ±0.1 mm

• gob weight ±5 g

• height ±0.2 mm

This ensures consistent pressure resistance for every bottle.

Annealing (Most Critical Step)

Bottles are reheated to 520–600°C and cooled slowly.

Without annealing → high breakage

Proper annealing → up to 80°C thermal shock resistance

Pressure & Impact Testing

Reliable suppliers test every batch:

✔ Internal pressure ≥ 1.2 MPa

✔ Drop test 1.2 m

✔ Heavy metal leaching

✔ Stress inspection

Production Quality Comparison

Defect Rate Comparison

Handmade → 2–3%

Fully automatic → <0.05%

For bulk orders, automated production is clearly safer and more economical.

Warehouse & Logistics Best Practices

Recommended:

✔ stack ≤ 8 layers

✔ use foam dividers

✔ stretch wrap pallets

✔ avoid sudden temperature changes

✔ allow acclimatization before filling

Industry Data & Market Trends

Glass remains the dominant packaging choice

According to:

OIV (International Organisation of Vine and Wine)

https://www.oiv.int

Statista Packaging Data

https://www.statista.com

Glass accounts for 70%+ of premium wine packaging due to:

✔ chemical stability

✔ oxygen barrier

✔ recyclability

✔ luxury perception

How to Choose a Reliable Glass Bottle Supplier

Professional suppliers should provide:

✔ SGS certification – https://www.sgs.com

✔ LFGB food-contact compliance

✔ fully automatic lines

✔ strict QC reports

✔ consistent batch quality

✔ bulk production capacity

Typical professional capability:

• 500,000+ bottles/day

• defect rate <0.05%

• stable delivery

• custom molds available

FAQ (Quick Answers)

Q1: Why do bottles break during filling?

Usually thermal shock or residual internal stress.

Q2: Are heavier bottles stronger?

Not always. Uniform thickness matters more.

Q3: Handmade or automatic?

Automatic lines provide far lower defect rates.

Q4: What pressure rating for sparkling wine?

≥ 1.0–1.2 MPa recommended.

Q5: How to reduce transport loss?

Foam dividers + stretch wrap + low stacking height.

Conclusion

Wine bottle cracking is not random.

It is preventable through:

✔ better materials

✔ precision forming

✔ proper annealing

✔ strict testing

✔ safe logistics

For bulk winery purchasers, choosing the right manufacturer eliminates most risks at the source.

CTA

Looking for:

• custom bottles

• sparkling-wine pressure bottles

• private molds

• bulk export supply

• SGS/LFGB compliant packaging

Contact our team today for samples and a fast quotation.