Blog

Handmade vs. Fully Automatic Glass Bottles

Which Production Method Is Right for Your Winery?

Wine and spirits producers often focus on branding, labels, and closures — yet one critical decision is frequently overlooked:

How are your glass bottles manufactured?

Should you choose handmade production or fully automated assembly line bottles?

Although both are made from the same glass materials, the manufacturing method directly impacts:

-

Filling efficiency

-

Quality consistency

-

Breakage rate

-

Long-term costs

-

Customization flexibility

Choosing the wrong type can slow down your bottling line or increase defects — while the right choice can improve productivity by 30% or more.

This guide explains the differences clearly so wineries can make smarter procurement decisions.

Why Production Method Matters More Than Most Buyers Realize

Before comparing both options, it's important to understand:

Glass bottle performance isn’t just about appearance.

For commercial wineries, small dimensional differences can cause:

-

Leakage

-

Capping failure

-

Machine downtime

-

Increased waste

-

Lower daily output

That’s why manufacturing precision is critical.

1. Quality Consistency & Precision

Handmade Bottles

Handmade or semi-manual production relies heavily on operator experience.

Common characteristics:

-

Slight height variations

-

Inconsistent bottom flatness

-

Small neck diameter differences

-

Less uniform wall thickness

While acceptable for small batches, these variations may cause instability in automated filling systems.

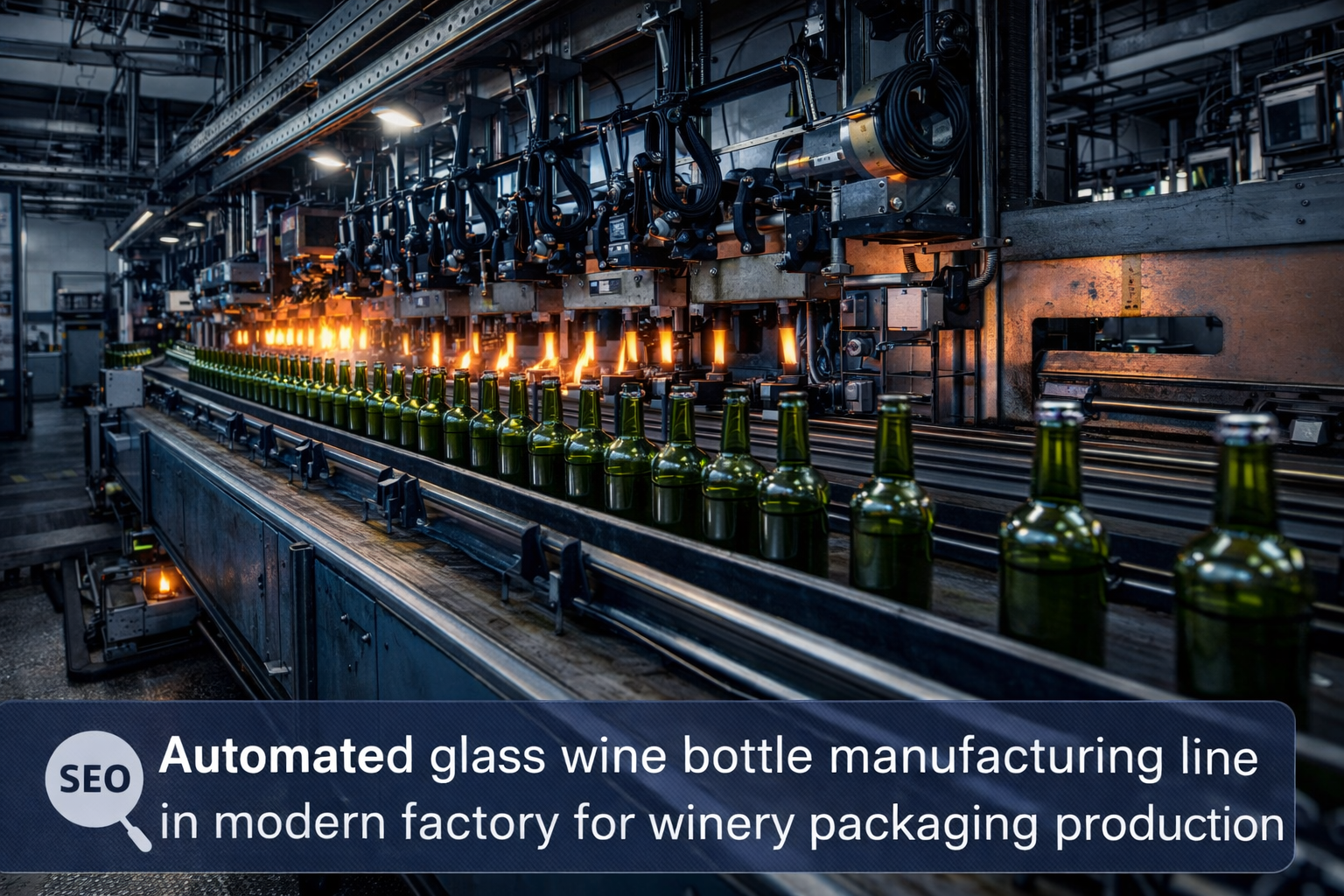

Automatic Assembly Line Bottles

Fully automatic production uses CNC-controlled systems:

-

Glass gob weight control ±5g

-

Identical forming pressure

-

Uniform cooling

-

Precise mold timing

Results:

✔ Identical dimensions

✔ Smooth surfaces

✔ Consistent neck finishes

✔ Perfect compatibility with filling machines

Leakage rate can drop below 0.01%.

2. Production Efficiency & Output

| Feature | Handmade | Automatic Line |

|---|---|---|

| Speed | Medium | Very high |

| Labor need | Higher | Lower |

| Filling stability | Moderate | Excellent |

| Output/day | Low–medium | Mass production |

Automated lines often improve bottling efficiency by 20–30%+, reducing downtime and labor costs.

For growing wineries, this difference quickly translates into real savings.

3. Customization & Design Flexibility

Handmade Production

Advantages:

-

Special shapes

-

Embossed logos

-

Heavy-bottom designs

-

Small batch runs

-

Faster mold changes

Ideal for:

-

Premium wines

-

Gift packaging

-

Limited editions

-

Boutique brands

Automatic Production

Better suited for:

-

Standard 750ml bottles

-

Large repeat orders

-

Stable SKUs

Changing molds requires more setup time and cost.

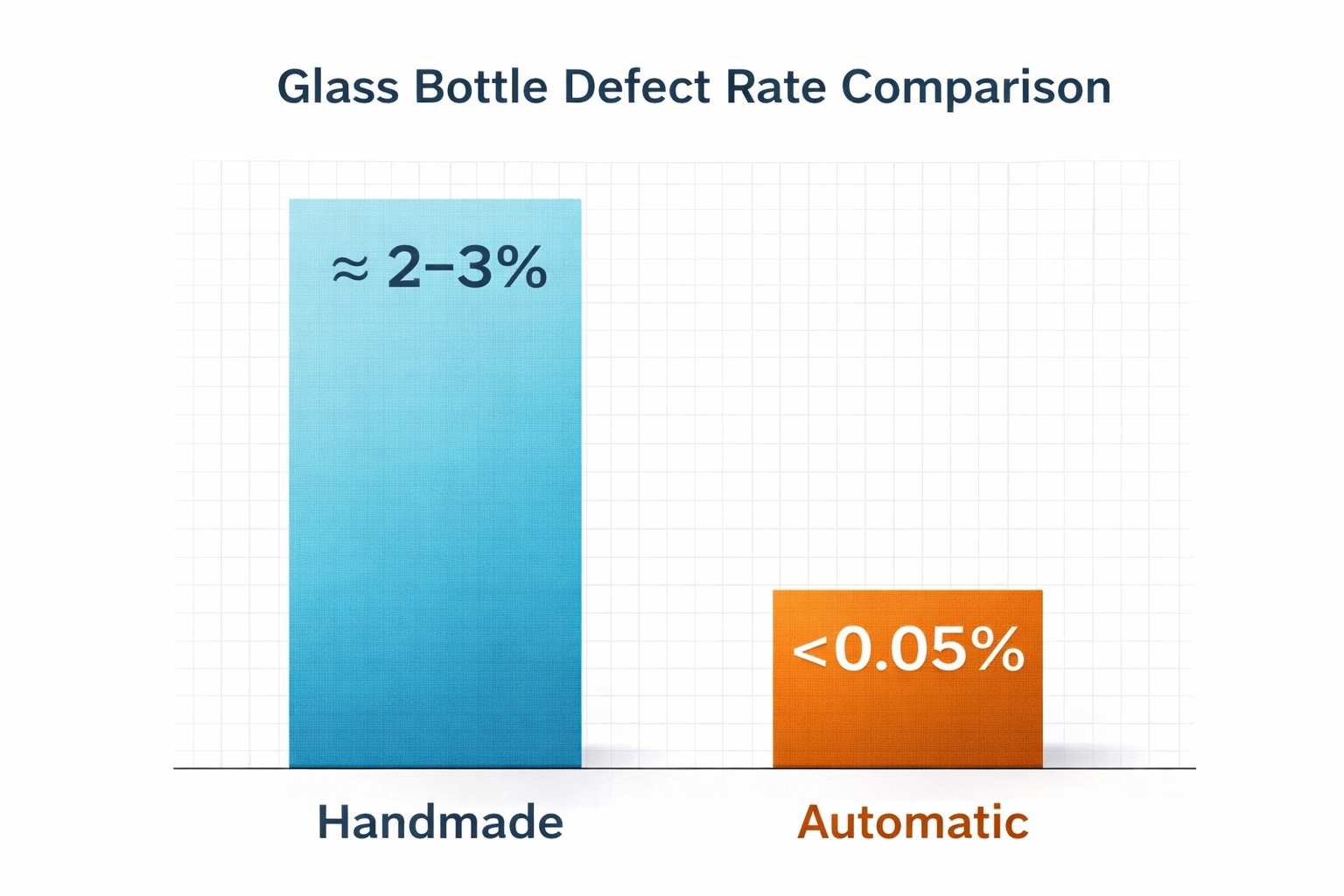

4. Defect Rate & Long-Term Stability

Handmade ≈ 2–3%

Automatic < 0.05%

Manual processes may cause:

-

Air bubbles

-

Wall unevenness

-

Visible seams

-

Neck misalignment

Automated control dramatically reduces these risks.

Lower defects mean:

✔ Less waste

✔ Lower replacement cost

✔ More stable supply

✔ Better brand reputation

5. Cost Structure & Order Volume

Handmade → Best for:

-

1,000–10,000 bottles

-

New product launches

-

Short runs

-

Lower mold cost

Automatic → Best for:

-

50,000+ bottles

-

Stable mass production

-

Lowest cost per unit

The larger the order, the more economical automated production becomes.

Quick Decision Guide for Wineries

| Your Need | Best Option |

|---|---|

| Custom shapes | Handmade |

| Small batch | Handmade |

| Premium gift bottles | Handmade |

| High-speed filling | Automatic |

| Large volume | Automatic |

| Lowest unit cost | Automatic |

Smart Strategy: Combining Both

Many professional manufacturers today integrate both systems.

This allows:

-

Automatic lines → bulk orders

-

Handmade lines → custom projects

Providing flexibility without sacrificing cost efficiency.

For wineries with multiple product tiers, this hybrid approach is often ideal.

Final Thoughts

There is no universal “best” method.

The right solution depends on:

-

Production scale

-

Packaging design

-

Budget

-

Filling technology

-

Brand positioning

By aligning bottle manufacturing with your operational needs, you can improve efficiency, reduce waste, and strengthen your market competitiveness.