Blog

Industrial Glass Packaging Engineering Partner|Precision Manufacturing for Wine, Spirits & Premium Packaging

Glass packaging is not simply produced — it is engineered.

For global wine producers, distilleries, and premium beverage brands, packaging must perform consistently across production lines, logistics networks, and international markets.

At COLORS GLASS, we operate as an Industrial Glass Packaging Engineering Partner, delivering:

-

Process-controlled manufacturing

-

Optical and structural consistency

-

Surface durability for high-speed filling

-

Reliable batch repeatability

-

Integrated packaging systems

We engineer packaging stability at scale.

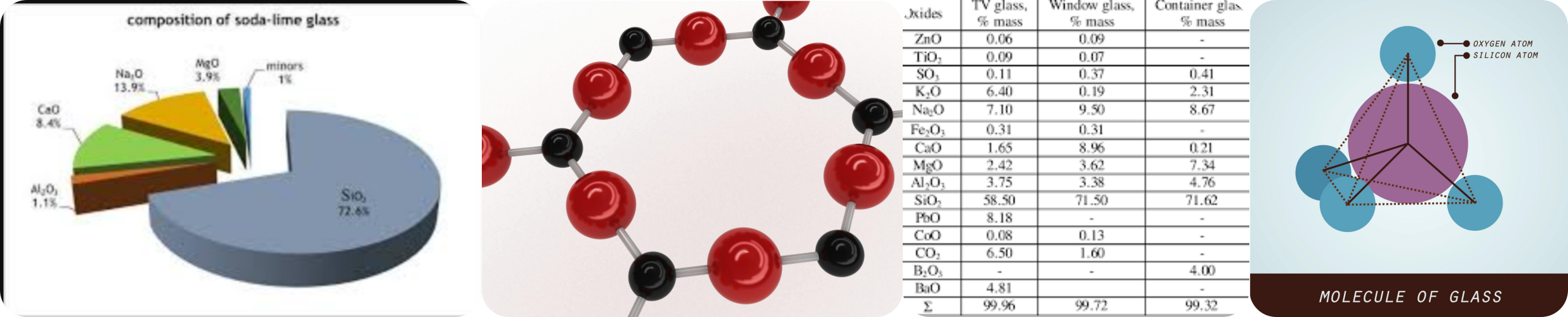

1. Engineering the Material Foundation

Industrial packaging begins with controlled raw materials.

Our production utilizes carefully selected silica, soda ash, and stabilizing oxides to ensure:

-

Chemical stability for alcoholic products

-

Controlled optical clarity

-

Long-term structural durability

Industrial Packaging Glass Composition

Typical Soda-Lime Glass Composition (Industry Range)

| Component | Typical % Range | Engineering Function |

|---|---|---|

| SiO₂ | 70–74% | Structural network former |

| Na₂O | 12–16% | Lowers melting temperature |

| CaO | 8–12% | Enhances chemical durability |

| Minor Oxides | <3% | Color & performance tuning |

Controlled formulation ensures resistance to alcohol exposure and long-term storage conditions.

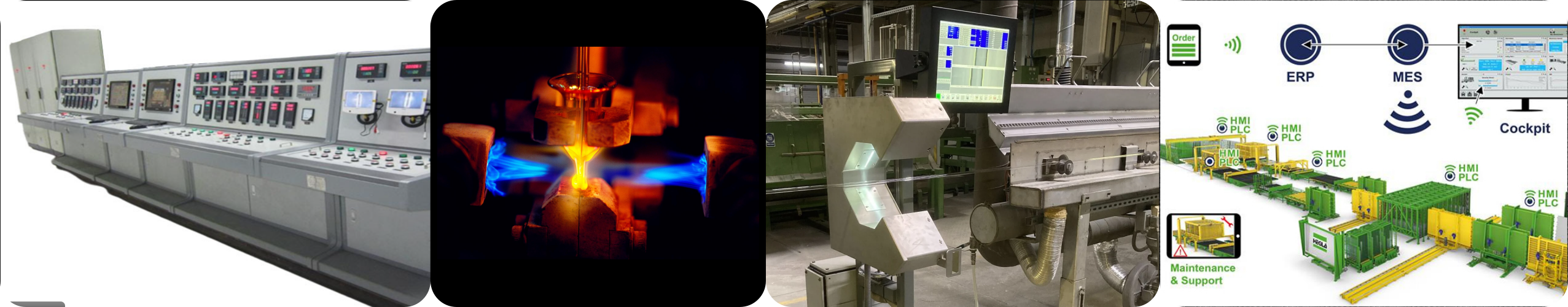

2. Furnace Engineering & Thermal Stability

Glass manufacturing is fundamentally a thermal engineering discipline.

Our production integrates:

-

Advanced furnace systems

-

Controlled melting curves

-

Stable oxidation-reduction balance

-

Real-time monitoring systems

Industrial Melting & Refining Curve

| Phase | Temperature Range | Engineering Purpose |

|---|---|---|

| Melting | 1500–1580°C | Dissolution of raw materials |

| Refining | 1450–1550°C | Bubble elimination & homogenization |

| Conditioning | 1100–1300°C | Viscosity stabilization |

Stable thermal control ensures:

-

Uniform oxide dissolution

-

Reduced inclusions

-

Consistent color

-

Mechanical integrity

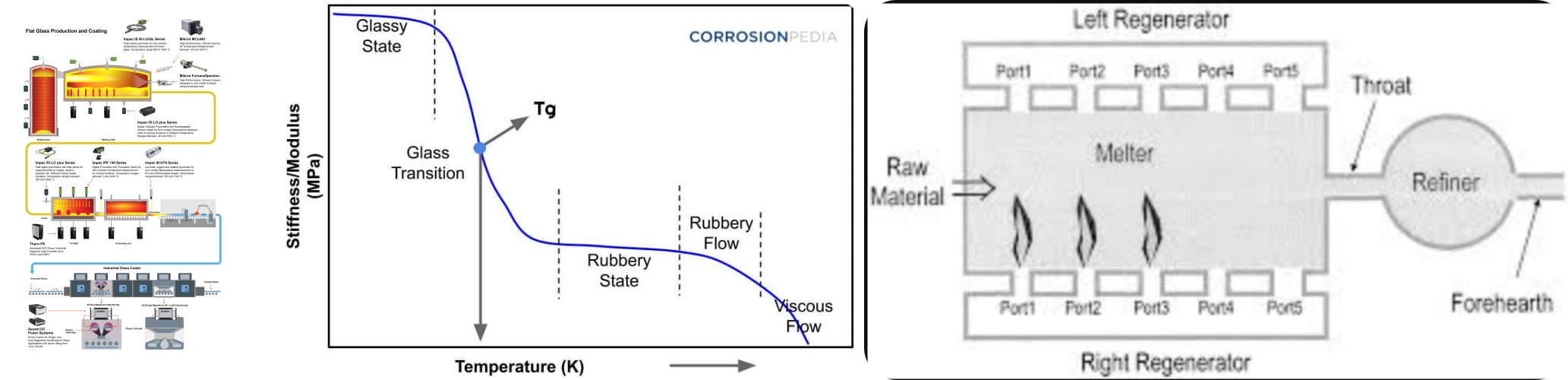

3. Surface Engineering for Industrial Performance

High-speed filling lines introduce friction, impact, and abrasion.

To enhance durability, COLORS GLASS applies:

-

Hot-end coating systems

-

Cold-end surface treatments

-

Silicon-enriched strengthening processes

Surface Friction & Durability Comparison

| Surface Condition | Relative Friction | Scratch Resistance | Filling-Line Stability |

|---|---|---|---|

| Untreated | High | Moderate | Variable |

| Hot-End Coated | Reduced | Improved | Stable |

| Hot + Cold-End | Low | High | Optimal |

Engineering surface control reduces:

-

Conveyor abrasion

-

Glass-to-glass scuffing

-

Production downtime

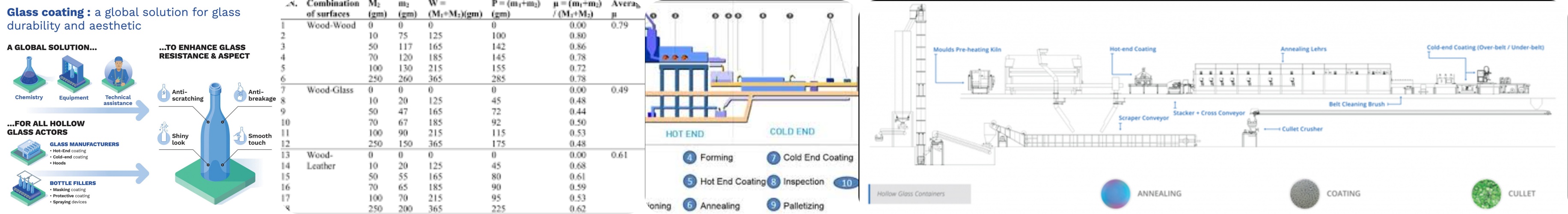

4. Optical & Color Precision Engineering

Color is engineered through:

-

Controlled oxide formulation

-

Furnace atmosphere balance

-

Stable batch dosing

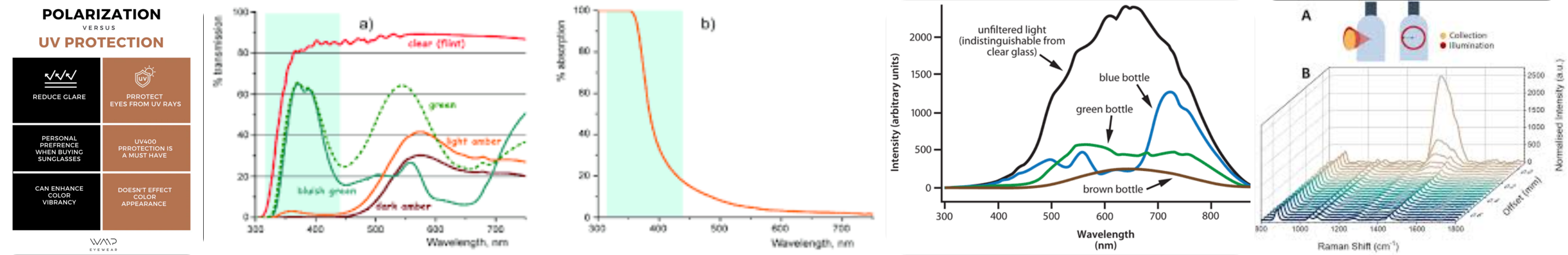

Light Transmission Reference

| Glass Type | Visible Light Transmission | UV Filtering | Typical Application |

|---|---|---|---|

| Flint | High | Low | Clear spirits |

| Green | Moderate | Moderate | Wine |

| Amber | Low | High | Whisky / Rum |

Controlled color engineering ensures predictable optical performance across warehouse and retail environments.

5. Integrated Industrial Capability

With over 3,000 mold sets and advanced equipment imported from Germany and Italy, COLORS GLASS supports:

-

OEM & ODM bottle development

-

Custom mold design

-

Closure integration (metal caps, aluminum caps, stoppers)

-

Carton packaging systems

-

Decoration services (embossing, frosting, hot stamping, screen printing)

Bulk Spirit Glass Bottles:

https://www.colorsglass.com/product/en/list/Product-20190820-030649-1.html

Bulk Red Wine Bottles:

https://www.colorsglass.com/product/en/list/Product-20190820-031103-1.html

Finishing & Decoration Services:

https://www.colorsglass.com/about/en/Info-20191120-015521.html

Contact Us:

https://www.colorsglass.com/about/en/contact-us.html

From Manufacturer to Engineering Partner

A supplier produces.

An engineering partner designs for performance.

COLORS GLASS integrates:

-

Material science

-

Thermal precision

-

Surface durability

-

Optical control

-

Batch repeatability

into every production cycle.

For global wine and spirits programs requiring industrial reliability, we deliver engineered glass packaging solutions — not just bottles.