Blog

Custom Glass Bottle Solutions for Filling Plants: A Practical Guide to Circular Packaging & Reuse Programs

Filling plants deal with glass bottles at scale—meaning glass impacts not only packaging aesthetics, but also line uptime, breakage rates, waste handling cost, and sustainability reporting. When circularity is designed into the bottle and managed on the plant floor, waste glass becomes a controlled material stream instead of a problem.

At Xuzhou Colors Glass Co.,ltd (https://www.colorsglass.com), we support filling plants with custom glass bottle solutions engineered for both branding and real production conditions—so your packaging can perform on the line while enabling reuse and recycling pathways.

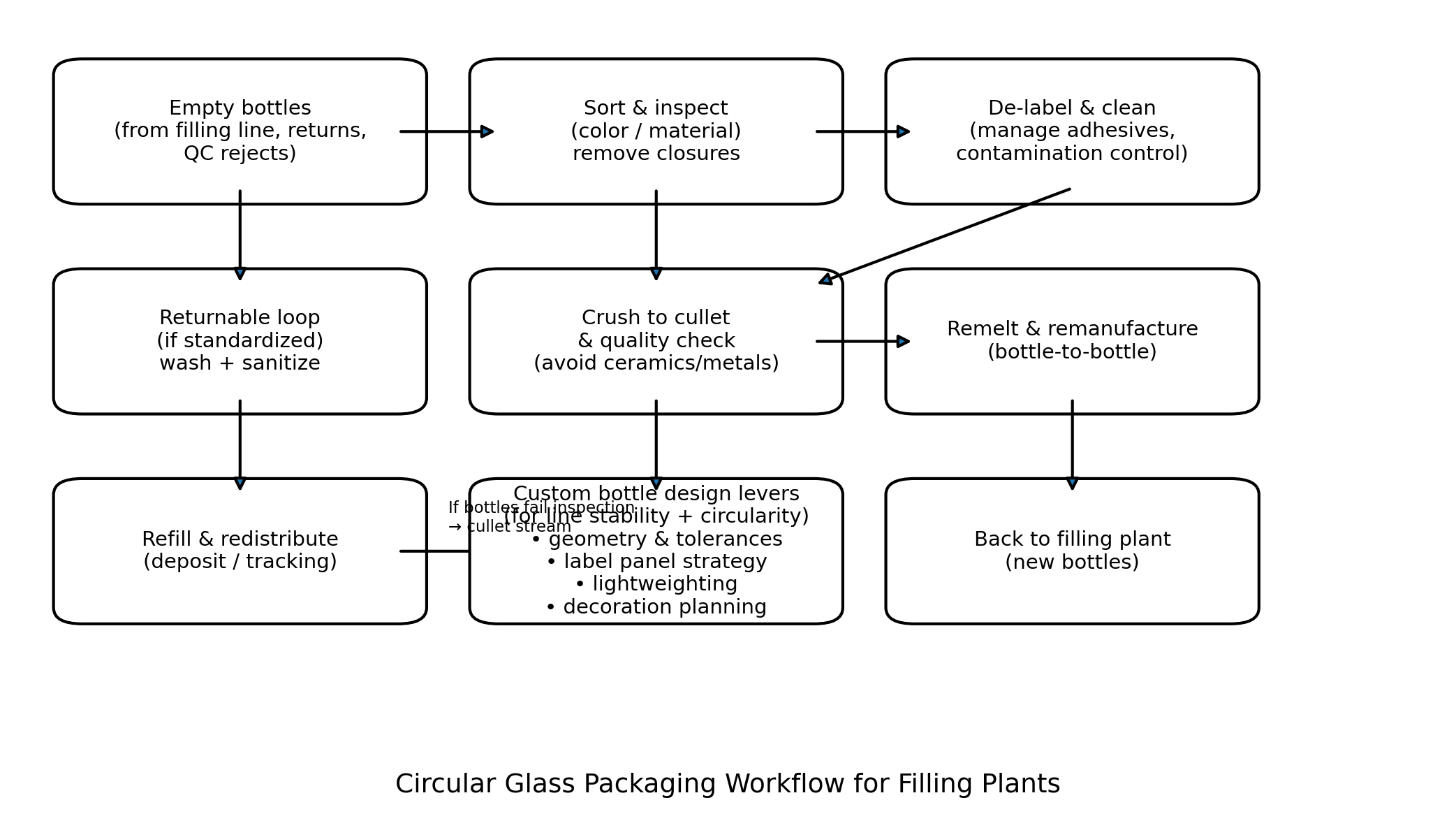

Visual: Circular Glass Packaging Workflow for Filling Plants

Image (workflow diagram):

This workflow shows two practical circular routes:

-

Bottle-to-cullet recycling (most scalable for high-volume mixed streams)

-

Returnable/refillable loop (highest circularity but requires standardization + wash/inspection systems)

1) Start with a Bottle Stream Audit (Fast, Practical, and High ROI)

Before choosing any circular strategy, audit what you really have:

-

Bottle mix: wine/spirits/RTD, standard vs unique shapes, minis

-

Color mix: flint/clear, green, amber (critical for recycling quality)

-

Contamination: labels/adhesives, closures, residual liquid

-

Breakage profile: where chips/breaks occur across your line

-

Logistics: storage bins/cages, pickup frequency, internal transport

This audit determines whether your best next step is cullet recycling, returnables, or controlled reuse.

2) The Scalable Baseline: Bottle-to-Cullet Recycling

For most filling plants, the fastest circular upgrade is strengthening your collection → sorting → cleaning → crushing (cullet) → remelt pipeline.

Industry groups note that glass can be recycled repeatedly and that higher cullet use supports energy and emissions reductions in glass manufacturing.

Reference: Glass Packaging Institute – https://www.gpi.org/facts-about-glass-recycling

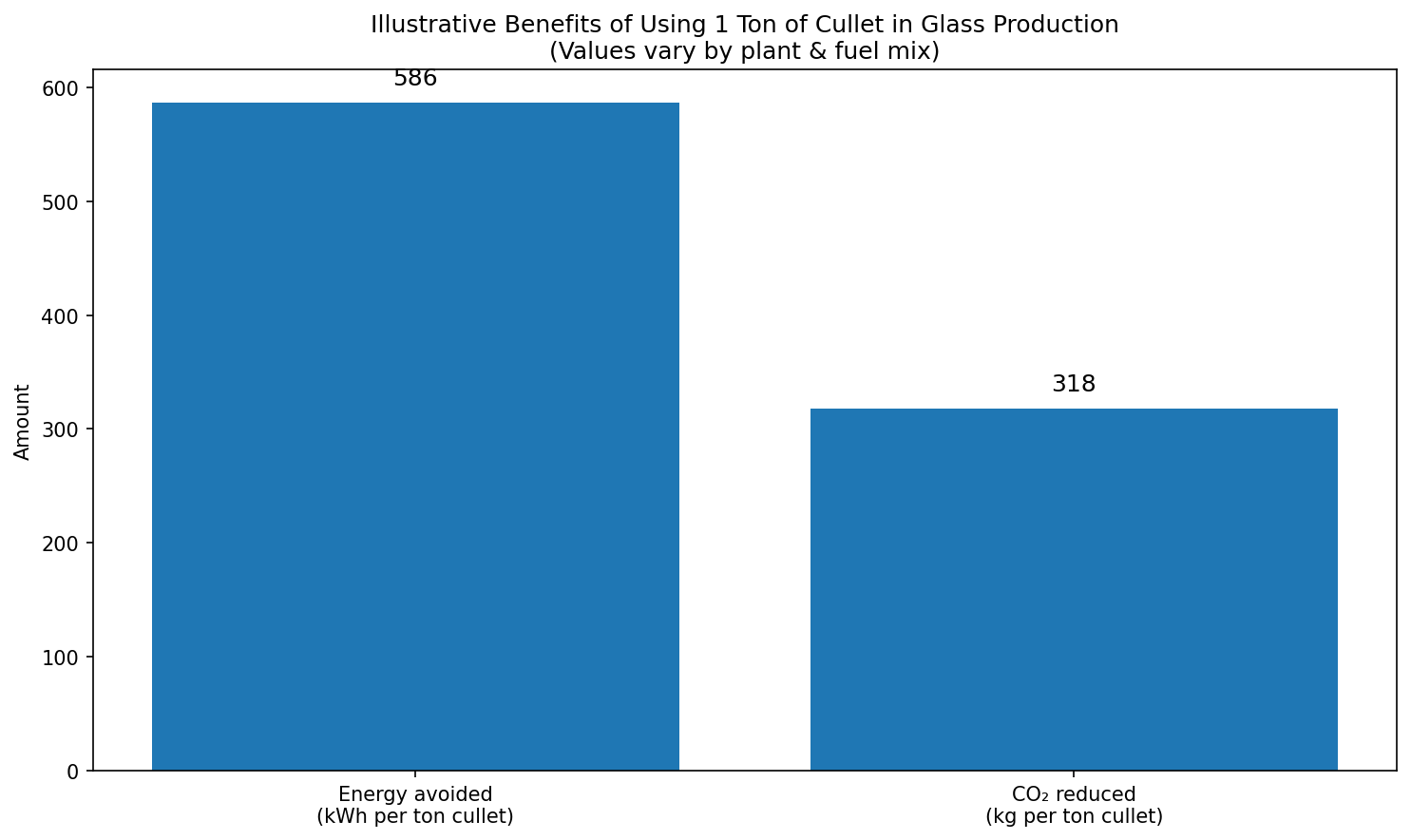

Visual: Illustrative Cullet Benefits

Image (chart):

Caption: Illustrative benefits of using 1 ton of cullet; actual savings vary by furnace design, fuel mix, and cullet quality.

Example industry figures for cullet-related reductions are discussed here:

Guardian Glass – https://www.guardianglass.com/us/en/who-we-are/stewardship/environmental-stewardship/life-cycle-of-glass/raw-materials/use-of-cullet-to-reduce-raw-materials-and-energy-consumption

For deeper technical context on energy implications, see this NREL PDF:

https://docs.nrel.gov/docs/legosti/old/5703.pdf

Plant-floor checklist (what actually makes it work)

-

Separate by color at source (avoid downcycling and rejection)

-

Contamination control (no ceramics/metals/stone mixed into glass)

-

Label & adhesive strategy aligned with recycler tolerance

-

Reliable logistics (standard bins/cages + scheduled pickup)

3) Returnable & Refillable Bottles (High Impact, Requires System Design)

Returnable systems can deliver stronger circularity, especially for regional distribution. But they demand standardization and operational discipline.

Best-fit scenarios:

-

local/regional distribution networks

-

hospitality channels with crate returns

-

subscription/club deliveries with planned returns

Core requirements:

-

standardized bottle geometry + consistent specs

-

wash/sanitize workflow (in-house or contracted)

-

inspection procedure for chips/cracks and cosmetic damage

-

deposit/refund policy and return tracking

EU-oriented industry updates and data-driven circular initiatives can be explored here:

Close the Glass Loop – https://closetheglassloop.eu/eurostat-2023-figures-reveal-74-9-eu-glass-recycling-rate/

4) Why Custom Bottle Design Is a Circularity Lever (Not Just Branding)

Circular packaging programs often fail for a simple reason: bottles were designed for shelf appeal, not for real filling-line conditions. Custom design can improve both runability and circular outcomes.

A) Reduce breakage and downtime

Key structural factors:

-

stable base geometry and standing ring design

-

shoulder/neck transitions for smooth starwheel transfer

-

heel radius and impact-resistance design

-

consistent dimensional tolerances for high-speed lines

B) Improve labeling and de-labeling outcomes

A recycling-ready bottle benefits from:

-

label panel geometry that supports clean application

-

surface consistency that avoids glue failures and residues

-

decoration planning that doesn’t complicate downstream processing

C) Lightweighting (only when engineered properly)

Lightweight bottles can reduce transport emissions—but only if mechanical performance remains stable under real line stress. Otherwise, breakage offsets sustainability gains.

5) Controlled Reuse Ideas That Don’t Disrupt Operations

Filling plants usually shouldn’t become craft studios. Choose low-risk, repeatable reuse:

-

controlled internal reuse for non-food applications (clearly labeled and compliant)

-

safe, inspected bottles for visitor-facing décor installations

-

donations to local education/art programs with consistent sorting rules

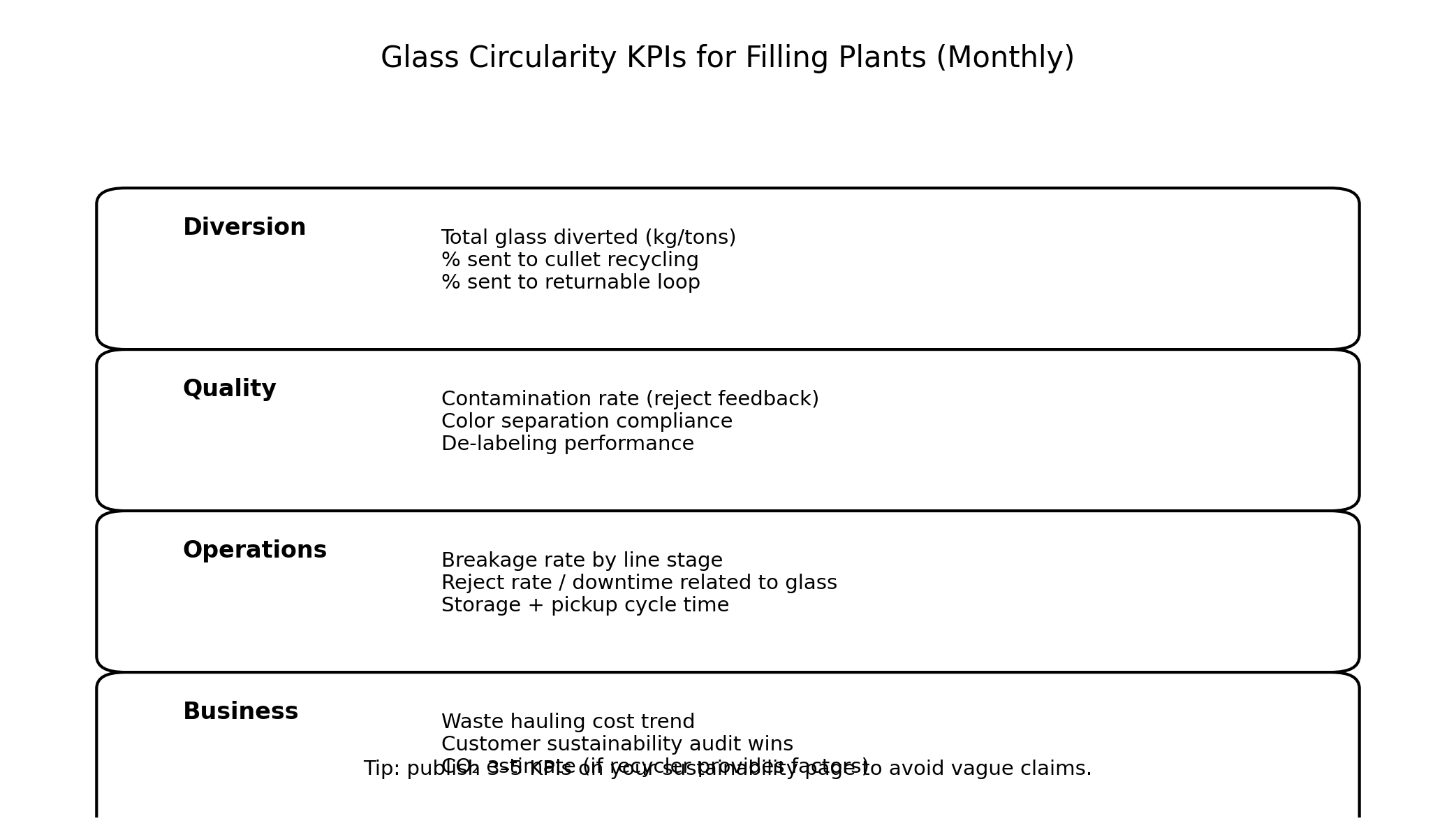

6) Publish KPIs to Make Sustainability Claims Credible

Visual: Monthly KPI Card for Filling Plants

Image (KPI card):

Recommended monthly KPIs:

-

total glass diverted (kg/tons) and % to cullet recycling

-

contamination rate (recycler reject feedback)

-

breakage rate by line stage

-

waste hauling cost trend

-

CO₂ estimate (if recycler provides factors)

If you want a public benchmark view, OWID provides an interactive glass recycling rates chart here:

https://ourworldindata.org/grapher/recycling-rates-glass

How We Support Filling Plants (Custom Bottles Built for Line Stability + Brand Differentiation)

At Xuzhou Colors Glass Co.,ltd (https://www.colorsglass.com), we help filling plants develop custom bottles that balance:

-

line compatibility (geometry + tolerance control)

-

decoration readiness (frosting, coating, printing, embossing zones)

-

circular readiness (label strategy, standardization options, recyclable-friendly decisions)

-

scalable production planning (sampling → pilot → mass production)

CTA (copy-ready):

Send us your line speed (bpm), target capacity, bottle reference drawings, and decoration requirements—we’ll propose a custom bottle structure optimized for stable running and circular packaging goals.