Blog

Glass Bottle Packaging Containers for Spirits & Wine: 700ml / 750ml / 1L Bulk Buyer Guide (Filling Lines, Closures & QC)

For wineries, distilleries, beverage brands, and filling plants, packaging is more than appearance—it affects product stability, filling-line efficiency, closure performance, and export breakage rates.

At Xuzhou Colors Glass Co., Ltd (Website: www.colorsglass.com), we manufacture and supply glass bottles for wholesale programs and OEM/ODM customization, supporting customers who need reliable packaging for automated filling lines and global distribution—especially in core formats: 700ml, 750ml, and 1L.

Factory & Bulk Readiness

Caption: Bulk programs rely on stable production flow and export-ready packing—palletization and standardized cartons help reduce breakage risks.

1) What Are Glass Bottle Packaging Containers?

Glass bottle packaging containers are rigid vessels formed from molten glass using industrial molding processes. For spirits and wine, glass remains a preferred choice because it offers:

-

Chemical stability (helps preserve aroma and taste)

-

Strong barrier performance against moisture and gases

-

Light protection when using colored glass (amber/green)

-

High compatibility with closures like bar-top and ROPP screw caps

Industry references (direct links):

-

Glass Packaging Institute (facts about glass): https://www.gpi.org/facts-about-glass

-

FEVE (why choose glass packaging): https://feve.org/about-glass/

2) Classification: How Bulk Buyers Choose Bottles

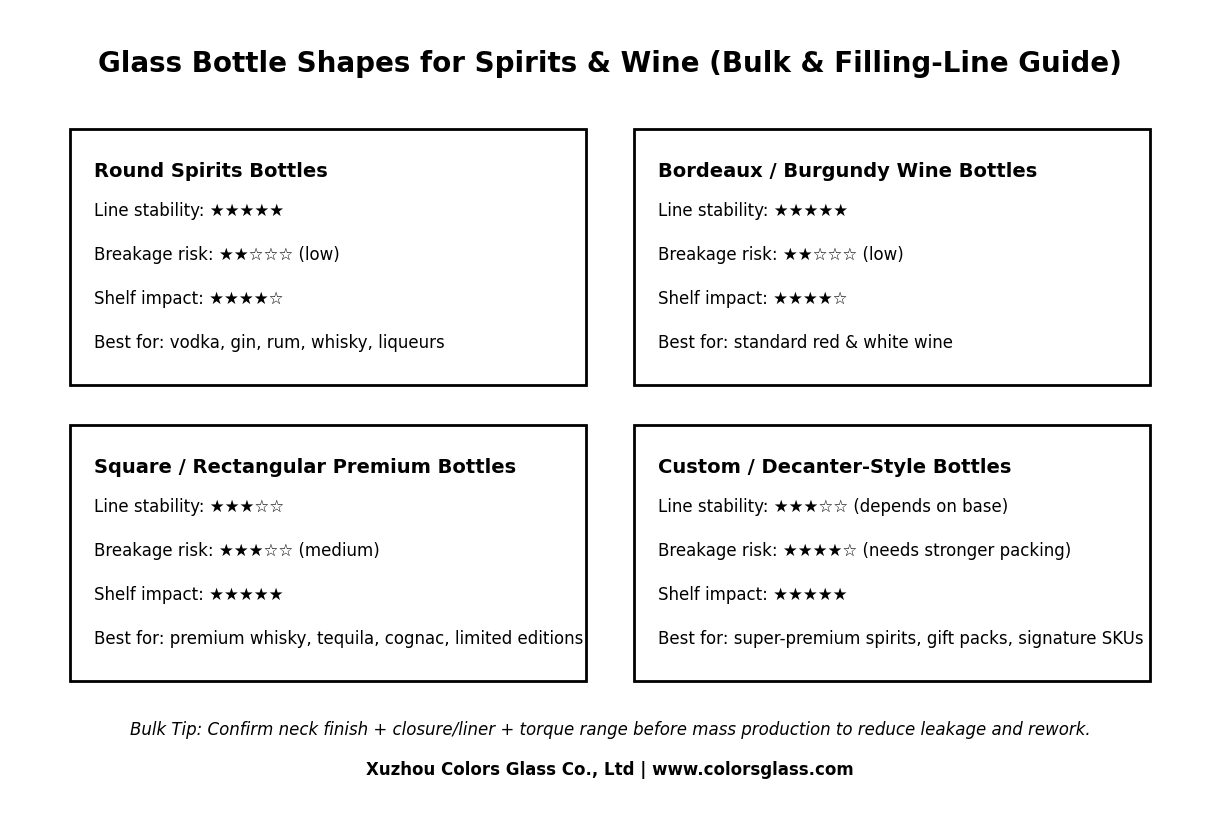

2.1 By Shape (Line Stability + Shelf Impact + Export Risk)

Bulk purchasers evaluate bottles by shape, because it affects conveying stability, packing efficiency, and shelf presence:

-

Round spirits bottles: highly line-friendly; often lower breakage risk

-

Standard wine bottles (Bordeaux/Burgundy): stable and standardized for large programs

-

Square / rectangular premium bottles: strong shelf impact; needs stronger export protection

-

Custom / decanter bottles: signature SKUs; base design + packing must be engineered

Caption: Quick reference for selecting bottle shapes based on filling-line stability, shelf impact, and export packing.

Production Line Consistency (Bulk Program Support)

Caption: Consistent forming and stable handling help keep key dimensions controlled—critical for closures and automated filling.

2.2 Core Volumes: 700ml vs 750ml vs 1L (Typical Use Cases)

In spirits and wine packaging, 700ml, 750ml, and 1L are the three core formats for bulk procurement. Choosing the right volume is not only marketing—it affects distribution, export planning, and line efficiency.

| Volume | Typical positioning | Common channels | Practical sourcing notes |

|---|---|---|---|

| 700ml | Mainstream spirits format; works for standard & premium | Retail spirits, bars, export bulk programs | Often paired with bar-top (premium) or ROPP (scale) |

| 750ml | Standard for wine; widely accepted for spirits too | Wine retail, restaurants, export, private label | Best “global anchor” for multi-region programs |

| 1L | Scale + value perception | Duty-free, wholesale/on-trade, select market preferences | Confirm carton partitions + pallets due to heavier packed loads |

Bulk Tip: Many brands use 750ml as the global base, with 700ml and 1L as market/channel-specific programs to reduce tooling duplication.

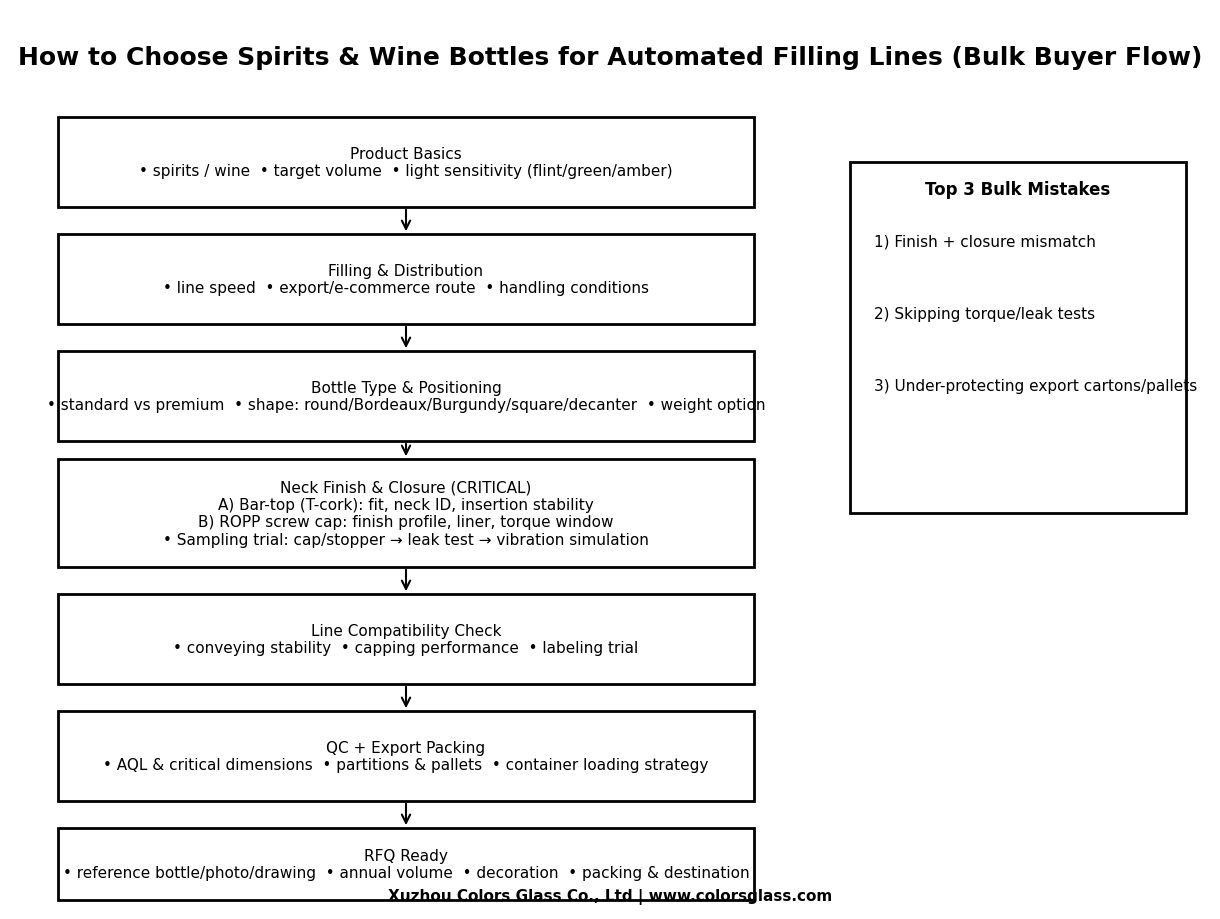

2.3 Mouth Size & Neck Finish (Critical for Filling Lines)

Most bulk issues happen when scaling to mass production without locking down finish + closure.

Before production, confirm:

-

Neck finish compatibility with your closure system

-

Liner/sealing surface match (especially for screw caps)

-

Torque range and performance on your capping machine

-

Sampling trial before mass run: cap/stopper → leak test → vibration/shipping simulation

Hot-End / Process Snapshot (Manufacturing Proof)

Caption: Process consistency supports stable dimensions—especially around finish/neck areas that impact sealing and capping.

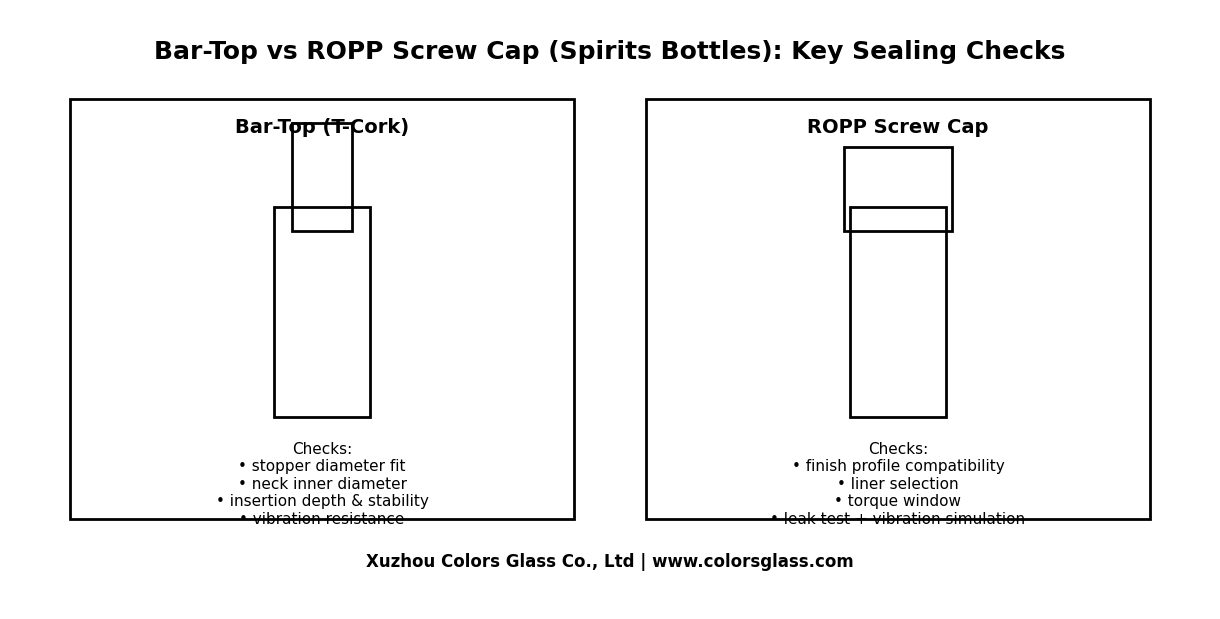

3) Bar-Top vs. ROPP Screw Cap (Spirits Packaging Comparison)

Choosing the right closure impacts sealing consistency, line speed, brand positioning, and shipping performance.

Caption: Bar-top supports premium positioning; ROPP supports fast, consistent sealing—both require finish/closure matching and sampling tests.

Practical Comparison Table

| Item | Bar-Top (T-Cork) Closure | ROPP Screw Cap Closure |

|---|---|---|

| Best for | Premium spirits & gifting SKUs (700ml/750ml common) | High-speed bulk programs (700ml/1L common) |

| Brand positioning | Strong premium cue, classic spirits look | Clean, modern, consistent for scale |

| Line speed & consistency | Usually slower; insertion depends on fit | Faster and stable for automated capping |

| Sealing focus | Stopper diameter fit + neck ID + insertion stability | Finish profile + liner + torque window |

| Leakage risk drivers | Stopper mismatch, insufficient insertion | Finish/liner mismatch, wrong torque |

| Sampling test | Fit trial + leak test + vibration | Cap trial + torque + leak + vibration |

QC / Verification Visual

Caption: Bulk programs should define QC standards and verify sealing/packing performance before mass production and export.

4) Bulk Buyer Checklist (Optimized for 700ml / 750ml / 1L)

-

Target format & positioning (700ml / 750ml / 1L; standard vs premium)

-

Bottle style (round/Bordeaux/Burgundy/square/decanter) + label panel needs

-

Closure system (bar-top or ROPP; liner + torque / fit + stability)

-

Line compatibility (conveying stability + capping trial + leak test)

-

QC criteria (critical dimensions + visual standards + traceability)

-

Export packing (carton partitions + pallets + container loading)

Caption: A production-oriented sourcing flow covering bottle type, closure choice, sampling tests, QC, and export packing for bulk programs.

Finished Bottles / Premium Look (Embossing Potential)

Caption: Premium programs often prioritize heavy base feel, decoration durability, and consistent finish for closures.

Export Packing & Breakage Control (Partitions + Pallets)

Caption: Strong partitions + pallet wrapping are essential to reduce breakage and claims in long-distance shipping.

5) Customization Options for Spirits & Wine (OEM/ODM)

Common customization for bulk programs:

-

Custom molds (signature silhouette / heavy base)

-

Embossed logos/text

-

Frosting / painting / screen printing / hot stamping

-

Batch color control for consistency

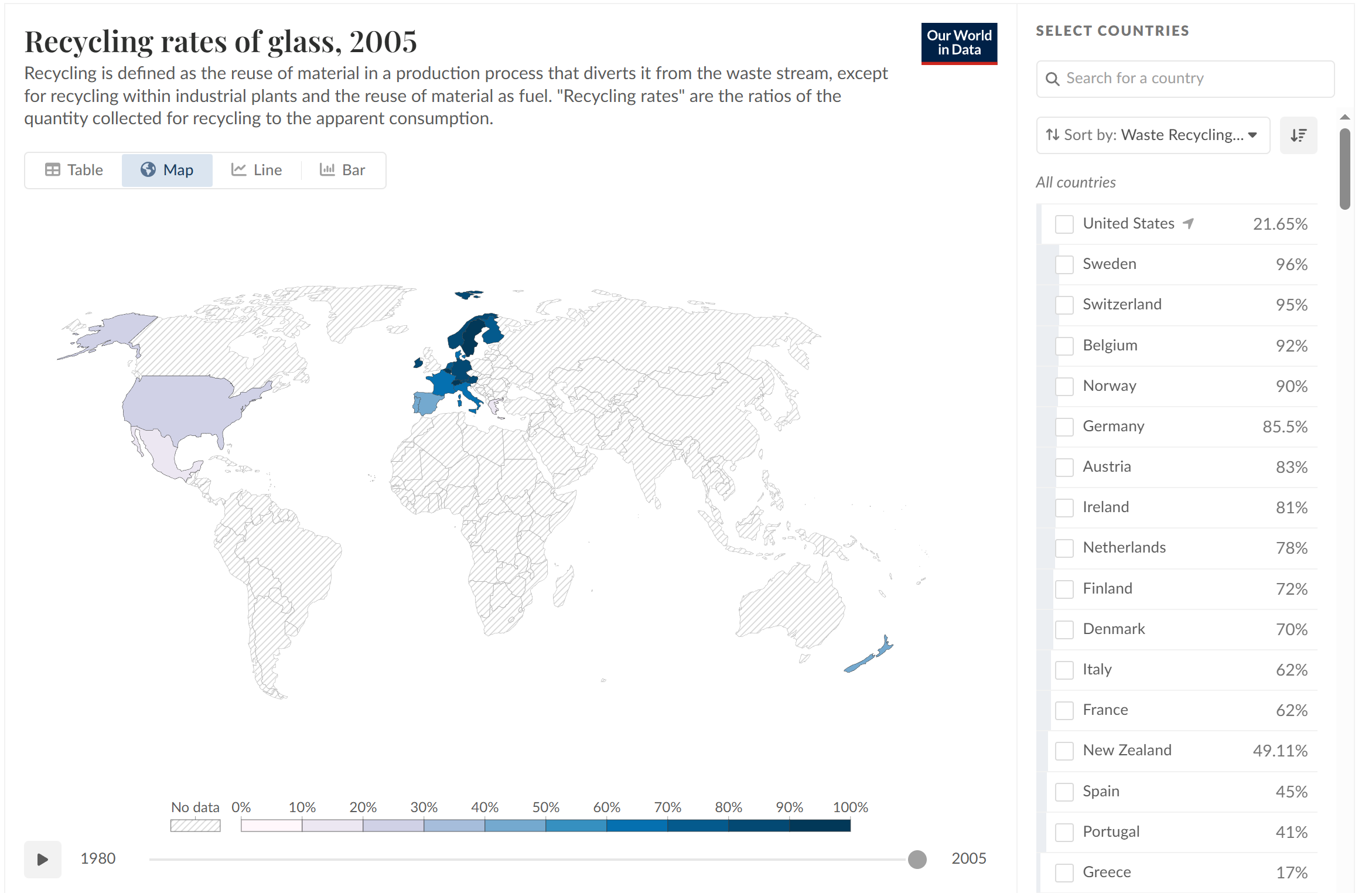

6) Optional Industry Data Link (Sustainability Reference)

If you want a data reference page for sustainability content, you can cite:

-

Our World in Data – glass recycling rates (interactive chart): https://ourworldindata.org/grapher/recycling-rates-glass

RFQ (Website Form Style): Request a Quote

Supplier: Xuzhou Colors Glass Co., Ltd

Website: www.colorsglass.com

A) Product & Volume

-

Product type (Spirits / Wine):

-

ABV% (if spirits):

-

Volume (700ml / 750ml / 1L — select one or multiple):

-

Target channel (Retail / On-trade / Duty-free / Private label / Export):

B) Bottle Style

-

Style (Round / Bordeaux / Burgundy / Square / Decanter):

-

Glass color (Flint / Green / Amber / Custom):

-

Weight (Standard / Premium / Heavy base):

C) Closure System (Choose One)

-

Closure type (Bar-top / ROPP screw cap):

-

If Bar-top: stopper style/size + premium look requirements

-

If ROPP: cap size + liner + target torque range

D) Decoration

-

Embossing (Yes/No):

-

Surface (Frosted / Painted / Screen printing / Hot stamping / Label only):

-

Labeling notes:

E) Quantity & Logistics

-

Trial qty:

-

First mass order qty:

-

Annual forecast (700ml/750ml/1L each if different):

-

Carton partitions + pallet requirement:

-

Destination port/country: