PERSONALIZATION

For both custom designs and catalogue products, COLORSGLASS offers a wide variety of personalization options through variations in capacity, glass colors, and types of corking or decorative container engraving.

UV Powder Coating & Graphic Wraps

UV Powder Coating & Graphic WrapsMake a statement while protecting contents from harmful UVA and UVB rays. COLORS offers affordable decorative solution that can help your brand stand out and appeal to a variety of consumers. Doing a limited edition run of wine? We have low minimums and highly affordable pricing on our decoration services. Contact our sales team to discuss your unique requirements. Click here to see examples of our bottle finishes.

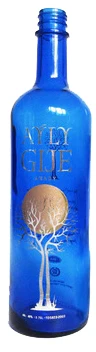

Gradation Coatings, Metallic Finishes, Frosting and Etching

Gradation Coatings, Metallic Finishes, Frosting and EtchingMany of our decorative surface finishes can be combined to deliver a bottle with high visual impact. Looking for a specific color or design that really speaks toward your brand? Contact our design department and we will work with you to achieve your vision. Click here to see examples of our bottle finishes.

Custom Embossing and Debossing

Custom Embossing and DebossingMany of our decorative surface finishes can be combined to deliver a bottle with high visual impact. Looking for a specific color or design that really speaks toward your brand? Contact our design department and we will work with you to achieve your vision. Click here to see examples of our bottle finishes.

Silk Screening & Hot Stamping

Silk Screening & Hot StampingCOLORS specializes in custom mold design. We'll take your logo and create a custom embossed or debossed mold design exclusively for you! Show your loyal customers who you really are and make your mark in glass. Talk to our engineering department about your exact needs.

MULTIPLE PROCESSES

We have three production units dedicated to decoration, which manage all of our finishing operations.

The list of services we offer is huge and non-exhaustive: screen printing (enamel, organic, precious metals), pad printing, decal printing, satin finishing, sandblasting, setting various accessories and savercoat spray coating, which involves colouring and satin-finishing the glass using a patented organic process, etc.

|

ENAMEL SCREEN PRINTING |

|

|

A process that enables enamels to be printed onto bottles using a screen. The production resources are automated. The decorable surfaces must generally be developable. Key advantages of enamel screen printing : Access to a very wide range of colours |

|

PRECIOUS METALS SCREEN PRINTING |

|

|

A process that enables precious metals to be printed onto bottles using a screen. The production resources are automated. The decorable surfaces must generally be developable. Key advantages of precious metal screen printing :

|

|

ORGANIC SCREEN PRINTING |

|

|

Decoration process that uses organic inks. Key advantages:

|

|

ACID-ETCHING |

|

|

This gives glass a dull or frosted effect and changes its texture. It is achieved by soaking in a bath of nascent hydrofluoric acid. The satin-finishing can be either full or partial, through application of a mask before the satin-finishing process.

Key advantages :

|

|

ACID-ETCHING WITH WINDOW |

|

|

This gives glass a dull or frosted effect and changes its texture. It is achieved by soaking in a bath of nascent hydrofluoric acid. The satin-finishing can be either full or partial, through application of a mask before the satin-finishing operation.

Key advantages :

|

|

SANDBLASTING |

|

| Sanding gives glass a frosted appearance. The texture can be more or less rough, depending on the grade used. Sandblasting reserves can be created, enabling patterns and insets to appear in specific areas of the bottle. |  |

TOTAL PRINTED |

|

|

The process offers a wide variety of colors and surface finish (glossy, matte, satin, etc.). It is fully eco-compatible because it uses water-soluble products.

Key advantages:

|

|

PARTIAL PRINTED |

|

|

The process offers a wide variety of colors and surface finish (glossy, matte, satin, etc.). It is fully eco-compatible because it uses water-soluble products.

Key advantages:

|

|

METALLIZATION |

|

|

This technology allows to create an upmarket package with an individual look. The glass is transformed into metal thanks to a fine metallic coating applied either totally or partially. Resulting in either a brilliant or matt aspect, in a myriad of metallic colors.

Key Advantages :

|

|

HOT STAMPING |

|

|

The object is to print a « film », i.e. a length of PET tape coated with fine layers of aluminium with a variety of aspects : gold, platinum, brilliantly coloured, satin-smooth or matt. This film is applied by direct stamp or by unwinding. Beforehand, the glass must be screen printed with an ink that will allow the film to adhere to the glass.

Key advantages :

|

|

TRANSFERS |

|

| Decals are images generally made up of several colours, in enamel or precious metals. They are produced by flat screen printing. They are laid by hand, after soaking in water, or automatically by transferring the image using a silicon pad. They enable those areas to be reached that cannot be screen printed in multiple colours, for which a greater tracking precision is required. |  |

SETTING ACCESSORIES |

|

|

This involves the automated or semi-automated setting of wax, metal, glass or plastic stamps, or any other accessory that enhances the product.

Key advantages :

|

|

PERSONALIZATION

For both custom designs and catalogue products, COLORSGLASS offers a wide variety of personalization options through variations in capacity, glass colors, and types of corking or decorative container engraving.

| This solution involves adapting a customized ring finish to items provided it is compatible technically with the existing moulds. This can be a standardised finish, a special finish or even a finish that is personalised with peripheral debossing . |  |

| This solution requires only the development of bases plates or in certain cases blank base moulds. This extends options for placing individual engraved elements on the base plate or inside the punt. |  |

| This principle is used to place an engraved feature in a medallion located on a bottle shoulder . Through this ingenious design with removable inserts placed on a selection of wine bottles this cresting technique is relatively economical because it does not involve the need of a full set of moulds.. Furthermore, this technique can be used to obtain incredibly precise definition and is highly reproducible. |  |

| This involves creating a new set of blow moulds that are compatible with the blank moulds already featured in the catalogue.This allows personalization through engravings that can be placed anywhere on the shoulder, body, or the base of a container. |  |

|

In some cases it is necessary to make full mould sets comprising blank and blow moulds, especially for :

|

|

|

"Bas Relief" is an ingenious solution that allows circular engraving to be positioned on the lower part of a bottle containing information such as the name of an area, geometrical friezes, or figurative scenes. As with the Cresting Insert option, COLORSGLASS has a series of mould sets for wine bottles designed with this technical principle to facilitate clients’ access to this type of feature |

|